Views: 2 Author: Site Editor Publish Time: 2024-04-24 Origin: Site

Introduction:

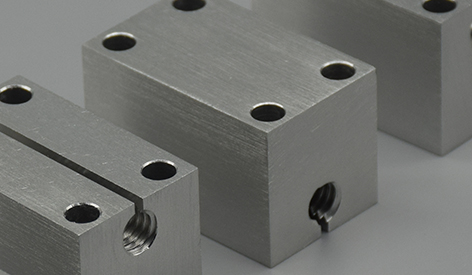

Small batch CNC machining plays a crucial role in modern manufacturing by offering cost-effective solutions and flexibility for producing limited quantities of precision parts. This article delves into the intricacies of small batch CNC machining, exploring cost reduction strategies, process optimization techniques, material considerations, and quality control measures to achieve efficient and economical production before transitioning to mass production.

1. Understanding Small Batch CNC Machining:

Small batch CNC machining involves the production of a limited number of parts using computer numerical control (CNC) machines. This approach is ideal for prototyping, testing, and initial production runs before scaling up to mass production. It offers advantages such as shorter lead times, reduced setup costs, and flexibility in design iterations.

2. Cost Reduction Strategies:

a. Design for Manufacturability (DFM): Implementing DFM principles early in the design phase minimizes complex features, reduces machining time, and optimizes material usage.

b. Material Selection: Choose cost-effective materials without compromising on quality and performance. Consider using standard stock sizes to minimize material waste.

c. Batch Consolidation: Combine multiple part designs into a single batch to maximize CNC machine utilization and reduce setup times and tool changes.

d. Optimize Toolpaths: Use efficient toolpath strategies, such as high-speed machining and adaptive toolpaths, to reduce machining time and tool wear.

e. Lean Manufacturing Practices: Implement lean principles to streamline workflows, eliminate non-value-added activities, and optimize resource utilization.

3. Process Optimization Techniques:

a. Advanced CNC Machining Technologies: Utilize advanced CNC machining technologies like 5-axis machining, robotic automation, and real-time monitoring systems to enhance productivity and accuracy.

b. Tooling Optimization: Invest in high-quality cutting tools, tool coatings, and tool life management strategies to improve machining efficiency and reduce tooling costs.

c. Fixture Design: Design ergonomic and modular fixtures to securely hold parts during machining, minimize setup time, and ensure consistent quality.

d. CNC Programming Optimization: Optimize CNC programs for efficiency, toolpath optimization, tool change optimization, and minimizing idle machine time.

4. Material Considerations:

a. Cost-Effective Materials: Select materials based on cost-effectiveness, performance requirements, and availability. Consider alternative materials with similar properties to reduce costs.

b. Stock Material Usage: Optimize stock material usage by nesting parts efficiently and minimizing material wastage during machining operations.

5. Quality Control Measures:

a. In-Process Inspection: Implement in-process inspection using advanced metrology tools like coordinate measuring machines (CMMs) and vision systems to detect defects early in the production process.

b. Statistical Process Control (SPC): Use SPC techniques to monitor process variability, identify trends, and ensure consistent quality throughout small batch production runs.

c. Continuous Improvement: Encourage a culture of continuous improvement to identify and address inefficiencies, optimize processes, and enhance overall quality and productivity.

Conclusion:

Small batch CNC machining offers significant cost reduction opportunities and operational efficiencies for manufacturers looking to produce limited quantities of precision parts. By implementing cost-effective strategies, optimizing processes, selecting suitable materials, and maintaining rigorous quality control, manufacturers can achieve cost-efficient production before transitioning to mass production, ensuring competitiveness and success in today's dynamic manufacturing landscape.