Views: 2 Author: Site Editor Publish Time: 2024-04-24 Origin: Site

Introduction:

Clear plastic molding has revolutionized various industries by providing unparalleled optics, transparency, structural integrity, and aesthetic appeal in product design. This article delves into the intricate details of clear plastic molding, its technological aspects, applications, advantages, and considerations for achieving superior optics, transparency, structure, and appearance.

1. The Science Behind Clear Plastic Molding:

Clear plastic molding involves the precise molding of thermoplastic materials with exceptional optical properties, such as polycarbonate (PC), acrylic (PMMA), and transparent thermoplastic polyurethane (TPU). The process employs techniques like injection molding, extrusion molding, or compression molding to create parts with outstanding clarity and transparency.

2. Technology and Equipment in Clear Plastic Molding:

Advanced technology and specialized equipment are paramount in clear plastic molding to ensure optimal optics and transparency. This includes high-precision injection molding machines, optical-grade molds, temperature-controlled environments, and sophisticated cooling systems to prevent defects and enhance structural integrity.

3. Advantages of Clear Plastic Molding:

· Superior Optics: Clear plastic molding enables the production of parts with excellent light transmission, minimal distortion, and high refractive indices, making them ideal for optical applications.

· Transparency: The process maintains exceptional transparency, allowing clear visibility through the molded parts, crucial for applications like lenses, windows, and displays.

· Structural Integrity: Clear plastic parts exhibit robust structural properties, including impact resistance, tensile strength, and dimensional stability, ensuring long-lasting performance.

· Aesthetic Appeal: The transparency and clarity of clear plastic parts contribute to a visually appealing and modern aesthetic, enhancing product appeal and customer satisfaction.

4. Applications of Clear Plastic Molding:

· Optical Components: Lenses, optical fibers, light guides, and display screens in electronic devices, cameras, and medical instruments.

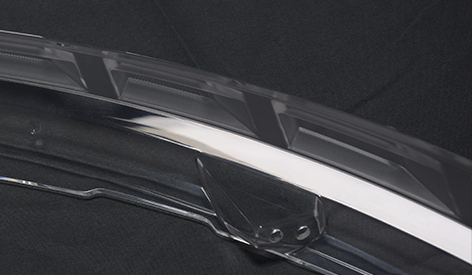

· Automotive: Clear lenses for headlights, taillights, and interior lighting, as well as transparent panels and windows.

· Medical Devices: Transparent housings, tubing, and containers for surgical instruments, diagnostic equipment, and medical packaging.

· Consumer Goods: Clear bottles, containers, packaging materials, and cosmetic cases for food, beverages, personal care products, and electronics.

· Aerospace: Transparent panels, canopies, and cockpit components for aircraft, ensuring visibility and safety.

5. Considerations for Optimal Results:

· Material Selection: Choosing the right clear plastic material based on optical requirements, chemical resistance, UV stability, and mechanical properties is crucial.

· Mold Design: Optimal mold design with considerations for gate placement, cooling channels, venting, and part geometry ensures uniform filling and minimal defects.

· Quality Control Measures: Rigorous quality checks, including visual inspection, optical testing, dimensional analysis, and surface finish evaluation, are essential for maintaining high standards of clarity and appearance.

· Surface Treatment: Post-molding processes like polishing, coating, or laser engraving may be employed to enhance surface smoothness, gloss, and scratch resistance for improved aesthetics.

Conclusion:

Clear plastic molding stands at the forefront of modern manufacturing, offering unparalleled optics, transparency, structural integrity, and aesthetic appeal across diverse industries. By leveraging advanced technology, material expertise, meticulous design, and stringent quality control measures, manufacturers can achieve exceptional results in clear plastic molding, meeting the demands of today's dynamic market and consumer expectations.