Views: 1 Author: Site Editor Publish Time: 2023-11-06 Origin: Site

Rapid prototyping technology offers several advantages for automotive impellers:

Faster Development: Rapid prototyping significantly reduces the time required to design, test, and iterate impeller designs. This accelerates the product development cycle.

Cost Savings: It minimizes the need for expensive tooling and molds, which can be a substantial cost in traditional manufacturing processes.

Customization: Rapid prototyping allows for the creation of custom impellers tailored to specific automotive applications, optimizing performance and efficiency.

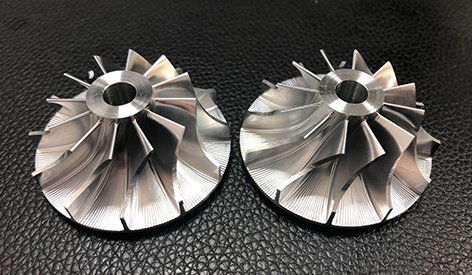

Complex Geometries: It enables the production of impellers with intricate and complex geometries that may be difficult or impossible to achieve with traditional manufacturing methods.

Iterative Testing: Design changes and iterations can be quickly implemented, facilitating multiple rounds of testing and refinement, leading to improved impeller performance.

Reduced Material Waste: Additive manufacturing, a common method in rapid prototyping, produces less material waste compared to subtractive processes.

Risk Mitigation: Rapid prototyping helps identify and rectify design flaws early in the development process, reducing the risk of costly errors in the final product.

Low-Volume Production: It is suitable for low-volume or one-off production runs, which is often the case during the initial stages of automotive component development.

Improved Communication: 3D models and physical prototypes make it easier to communicate design ideas and concepts among team members and stakeholders.

Testing and Validation: Functional prototypes can be used for testing and validation, ensuring impeller performance meets design specifications.

Materials Variety: Various materials, including metals and plastics, can be used in rapid prototyping, allowing for material selection optimization.

In the automotive industry, where impellers play a critical role in engine cooling, air conditioning, and other systems, rapid prototyping helps streamline the design process, improve impeller efficiency, and bring products to market faster and at a lower cost.